Beyond the datasheet: How to get more out of your primary cell batteries

Low cost and convenience make primary cells popular with developers and consumers. Modern ultra-low-power design means devices can run for years before changing their batteries. Although long battery life has created a fit-and-forget attitude toward primary cell batteries, if a device runs on stored power, at some point the power will run out.

Most primary cell battery-powered devices don’t use power management. Instead, they rely on the battery voltage being stable. When the voltage falls below the circuit’s minimum operating voltage, the batteries must be replaced.

Many modern ICs are designed to operate from a relatively wide supply, between 1.8 V to 3.4 V, for example. When a battery voltage falls below the circuit’s minimum operating voltage it would probably be replaced, even if it still has energy to give. With so many millions of primary cell batteries replaced every day, we should be working harder to get all available energy out of every one of them.

A boost converter can make use of that latent energy and some primary cell applications may include one if needed. Power management integrated circuits (PMICs) often include a boost converter to provide stable power, but most PMICs are complex devices with multiple voltage domains. They can be large, expensive, and not designed for single-rail applications running on primary cell batteries.

The nPM2100 from Nordic Semiconductor is different. As the first PMIC from Nordic designed specifically for primary cell applications, the nPM2100 addresses the gap in the market. It is also the smallest device Nordic has ever made, measuring just 1.9 mm by 1.9 mm in the chip-scale package option.

Unique features of the nPM2100

The new PMIC has been designed to extend the usable lifetime of primary cell batteries. Although mainly aimed at supporting Nordic’s low-power wireless (Bluetooth, Thread, Matter, Zigbee) devices, it can be used in any battery-powered device, connected or not, to get the most out of a primary cell.

Many power-related features of the nPM2100 help it do this and make it stand out. The features we’ll look at are:

- The ultra-efficient boost converter–up to 95% efficient

- A unique ship mode so batteries can be factory-fitted

- A hibernate mode with low-power sleep timer to extend battery lifetime

- An innovative fuel gauge to estimate battery lifetime

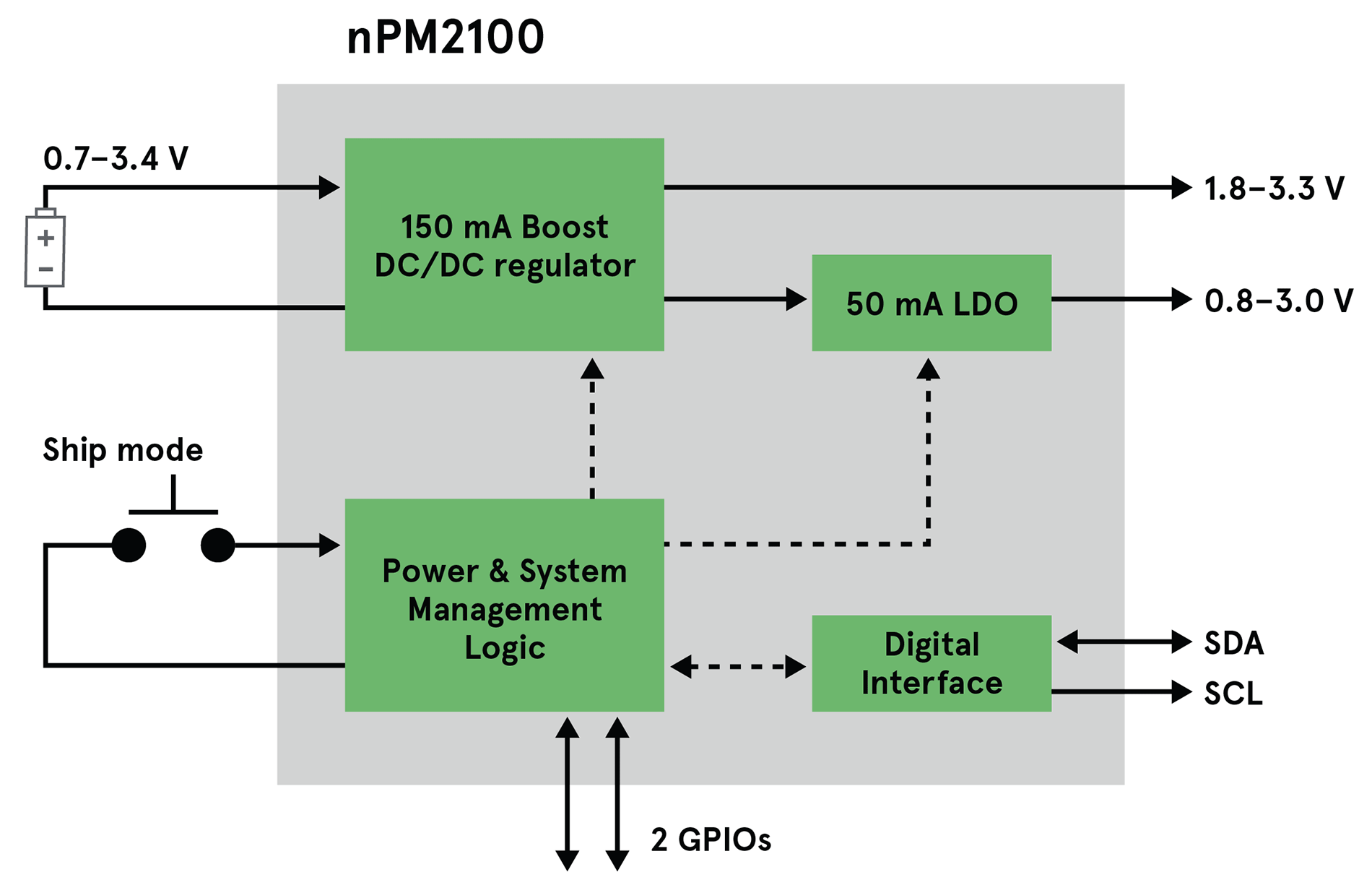

Figure 1: The nPM2100 PMIC

As Figure 1 shows, the main output voltage can be set at between 1.8 and 3.3 V. The boost converter can deliver this output voltage even when the battery voltage is as low as 0.7 V. The boost converter starts working when the battery voltage drops to 3.0 V and continues working until the battery voltage falls below the minimum input voltage. It means the nPM2100 can deliver 3.3 V at up to 150 mA all the time the battery voltage is above 0.7 V, providing the battery’s internal resistance doesn’t restrict the boost converter’s input current.

The main converter isn’t buck/boost so the nPM2100 doesn’t regulate down, but there is an integrated low dropout (LDO) regulator, fed by the output of the boost converter and capable of delivering up to 50 mA. The LDO is also controlled by software through the two-wire port. Its output can be set to between 0.8 V and 3.0 V and adjusted in 50 mV steps. It can also be used as a load switch.

The power rail could be as high as 3.4 V when new batteries are fitted, so any components on the main voltage rail must be capable of withstanding the higher battery voltage. But as many small devices powered from primary cell batteries often don’t include any kind of voltage regulator or power management, that is not a limitation.

In the context of small devices such as smart sensors, 150 mA peak current is a lot. For context, the nRF54L15 multiprotocol wireless microcontroller, often used in connected devices running on primary cell batteries, requires less than 10 mA when transmitting at 8 dBm, and just 4.8 mA at 0 dBm. Nordic designed the PMIC to support this kind of device, but it can be used in any battery-powered design that requires between 1.8 and 3.0 V at less than 150 mA peak current. Many devices will need much less than 150 mA peak current.

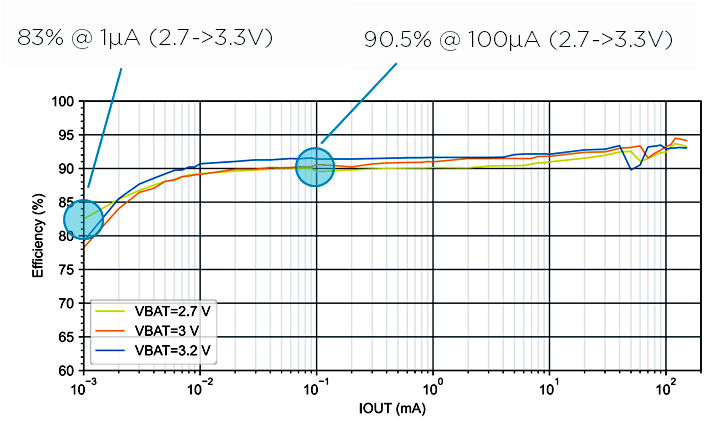

The efficiency of the boost converter sets the standard for primary cell PMICs: up to 95 % efficient at 70 mA and 90.5 % at 100 µA for a supply voltage of between 2.7 and 3.3 V.

Figure 2: Efficiency of the nPM2100 boost converter

When batteries are included

Factory-fitting primary cell batteries has advantages. The consumer gets a better out-of-the-box experience, it can reduce packaging and the manufacturer doesn’t have to add that small tag to isolate the battery terminal. These are additions that increase plastic waste and impact the design of the product.

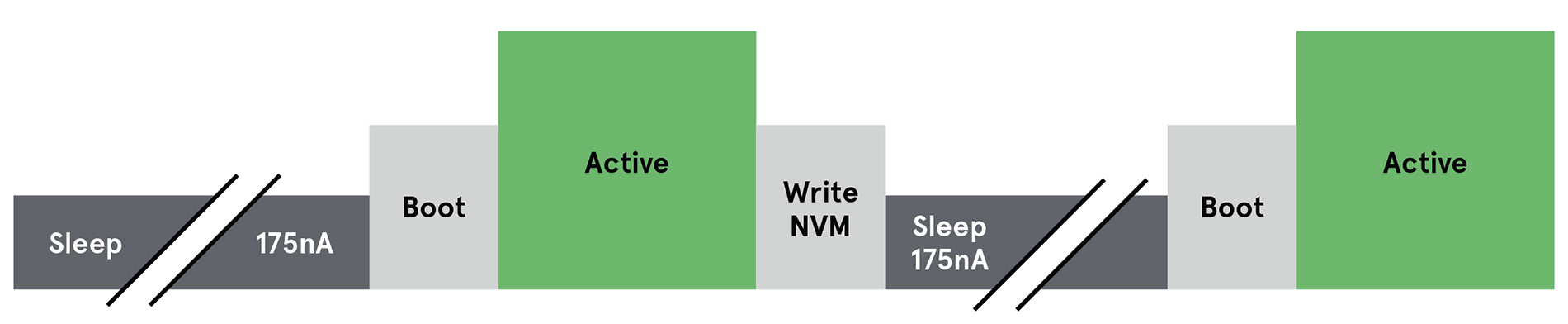

When used as intended, the nPM2100 assumes complete control of the voltage rail. This includes a low-power mode that isolates the batteries; only the PMIC is powered. This mode can be used during shipping and when the product isn’t operating. Ship mode, as Nordic has named it, only draws 35 nA, which is less than the self-discharge current of popular alkaline or lithium manganese dioxide primary cell batteries.

The nPM2100 can enter and exit ship mode in two ways: programmatically, or by pulling the SHPHLD pin high or low. The options for using the SHPHLD pin can be set through registers, to detect either a falling-edge or rising-edge on SHPHLD. The pin can also be configured as break-to-wake, whereby a connection between SHPHLD and ground is broken to wake the PMIC.

To save power during normal operation, Nordic has included a hibernate mode. This mode uses the PMIC’s timer and although it uses more power than ship mode, the device wakes from hibernate mode faster. This means hibernate mode can be used more often, to save battery power without impacting the user experience. The maximum hibernate time available using the timer is three days.

Figure 3: Hibernate mode

Software fuel gauge

Knowing how much energy is in a primary cell battery is more complex than simply measuring the voltage across the terminals. Temperature plays an important role. Nordic has developed software algorithms that use voltage and temperature to gauge the energy left in a battery. The algorithm is tuned to the chemistry of the battery.

The nPM2100 includes a temperature sensor. Customers can integrate Nordic’s algorithm for their battery type into their application code. This provides more accurate estimation of the energy available and when the primary cells need to be changed.

Other innovative features

In addition to the highly efficient boost converter, the nPM2100 features two general-purpose input/output (GPIO) pins, configured using registers. An on-chip analog/digital converter (ADC) is used to measure the battery voltage, output voltage, and read the on-chip temperature sensor. The ADC can be configured to perform single-shot or timed conversions. One option here is to use a GPIO as an interrupt to alert the host microcontroller when a measurement has been completed.

The nPM2100 also includes two common PMIC functions: a boot monitor and watchdog timer. The boot monitor power-cycles the host processor or system-on-chip if it fails to boot correctly. The watchdog timer triggers a system reset or, alternatively, power cycles the system if the host fails to reset the watchdog in the preconfigured time period. Both functions are unaffected by power cycling or system reset.

To learn more about the nPM2100 and how it can benefit your next battery-powered design, contact your local Avnet representative.